BIOCHAR PRODUCTION MACHINE

The Biochar Machine is engineered to convert agricultural waste, wood residues, coconut shells, sawdust, and organic biomass into high-quality biochar using efficient thermochemical processing. This system supports businesses that aim to create renewable fuel products, soil-enhancement materials, and carbon-sequestration solutions. Built for durability and consistent output, the biochar machine is suitable for farms, recycling units, biomass industries, and commercial production facilities.

Key Functional Capabilities of the Biochar Machine

Maintains steady temperature control for complete and uniform biomass carbonization.

Optimized airflow ensures consistent heating without compromising biochar structure.

Supports various applications such as soil conditioning, industrial filtration, biomass fuel, and activated carbon pre-processing.

Designed to deliver stable performance for both small and large-scale operations.

Compact layout and controlled heating mechanisms allow easy integration into new or existing facilities.

The Biochar Machine also supports clean processing with reduced emissions and efficient fuel usage, helping operators lower production costs while maximizing conversion efficiency. Its strong build quality and advanced internal configuration ensure long service life and dependable operation across various biomass conditions.

HOW THE BIOCHAR PRODUCTION PROCESS WORKS

The Biochar production sequence follows a controlled thermal decomposition method inside an oxygen-limited environment. Here is a simplified overview of the production cycle:

Step 1: Biomass Feeding & Preparation

Organic material such as wood chips, coconut shells, husk, or agricultural waste is loaded into the system after basic size reduction and drying.

Step 2: Controlled Heating Phase

The biomass is heated in a sealed chamber where oxygen is restricted. This initiates the carbonization process without burning the material.

Step 3: Carbonization Process

The material breaks down into charcoal-rich biochar. Volatile gases produced during this stage can be reused internally as fuel, improving efficiency.

Step 4: Biochar Collection & Cooling

Finished biochar is discharged and cooled safely to maintain structure and prevent re-ignition.

Step 5: Final Output

The resulting biochar can be used for:

Soil enhancement and agricultural applications

Water and air filtration

Renewable heating fuel

Industrial absorbents

Carbon-negative environmental projects

EXPLORE OUR RANGE OF HIGH-PERFORMANCE BIOCHAR MACHINES

EXPLORE OUR RANGE OF HIGH-PERFORMANCE

BIOCHAR MACHINES

VEERA BP100C - BIOCHAR PRODUCTION MACHINE

$25000 / Unit

The VEERA BP100C is engineered for controlled biochar manufacturing using agricultural and organic biomass. Designed for steady thermal processing, this unit delivers uniform char quality while maintaining low energy consumption. Its compact industrial design makes it ideal for small-to-mid capacity operations focused on sustainable carbon production.

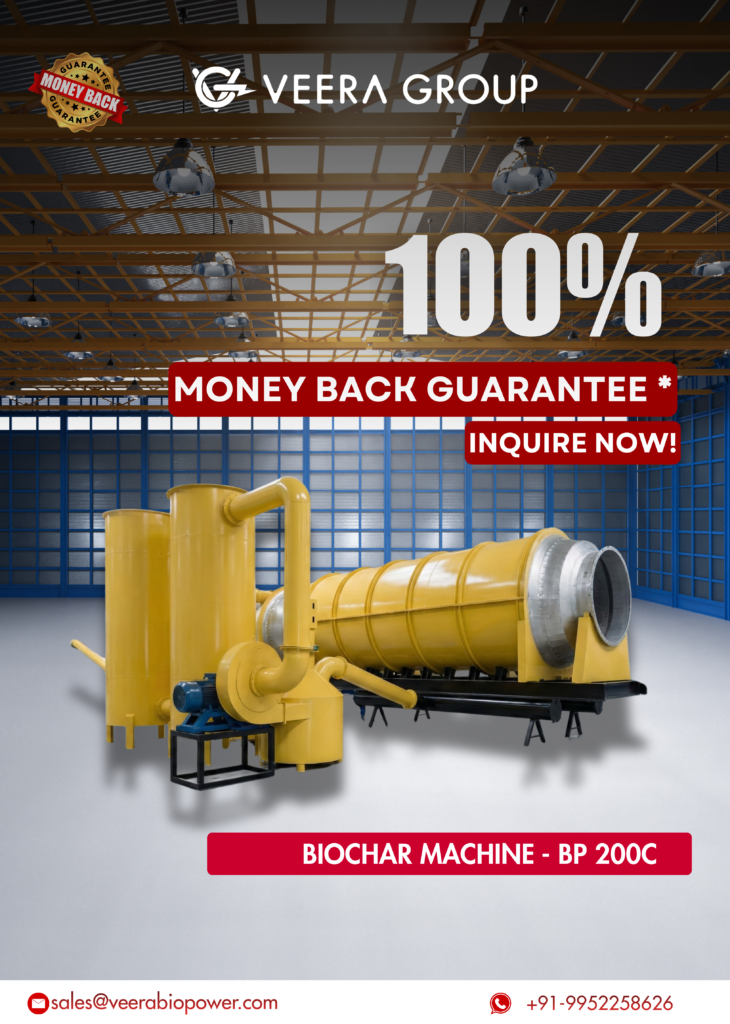

VEERA BP200C - HIGH-CAPACITY BIOCHAR PRODUCTION MACHINE

$35000 / Unit

The VEERA BP200C is designed for higher-capacity biochar production, offering stable thermal conversion and consistent carbon output from a wide range of biomass materials. Built for continuous operation, it combines efficient heat management with robust construction, making it suitable for commercial and industrial biochar manufacturing setups.

WHY OUR BIOCHAR MACHINE IS A RELIABLE CHOICE

Manufactured by Veera Group, this system combines strong construction, refined heating control, and dependable component quality to deliver stable production in demanding environments. Each model is engineered to maintain uniform biochar output, reduce downtime, and perform consistently over long operating hours. With flexible capacity options and long-term operational value, the biochar machine supports both expanding businesses and established biomass processing units.

READY TO BEGIN YOUR BIOCHAR PRODUCTION SETUP?

Veera Group can help you select the right machine model, discuss capacity requirements, provide cost details, and support installation planning. Share your project goals and we’ll guide you Beyond with the right solution.

FAQs

What biomass materials can the Biochar Machine process?

The system can process wood residues, coconut shells, agricultural waste, husk, and sawdust—essentially any dry biomass suitable for controlled carbonization.

What is the typical production capacity?

Output depends on the selected model, but machines are available in small, medium, and industrial capacities designed to support consistent, high-volume carbonization cycles.

Does the Biochar Machine support continuous operation?

Yes, selected models are built for continuous production with controlled heating and efficient airflow for uninterrupted carbonization.

Which industries generally use this machine?

The machine is commonly used in agriculture, biomass recycling, environmental projects, filtration media production, and renewable fuel manufacturing.

Does Veera Group provide installation and operator training?

Yes, Veera Group offers installation support, operational training, and ongoing technical assistance for all machine models.