BIODIESEL MACHINE

The Biodiesel Machine is engineered to convert used cooking oil, animal fats, vegetable oils, and waste industrial oils into fuel-grade biodiesel through a controlled transesterification process. Built for consistent output and long-term industrial use, this system supports recycling plants, fuel production units, commercial farms, and businesses looking to create clean-burning, renewable energy.

Designed for reliable operation, the Biodiesel Machine maintains steady heating, precise mixing, and stable reaction control. It ensures high-purity biodiesel with reduced impurities, balanced viscosity, and excellent combustion performance—making it suitable for both small and large-scale production setups. With durable components, structured workflow, and well-tested engineering, the system consistently delivers strong conversion efficiency and dependable production output.

The machine also helps operators reduce fuel production costs by optimizing catalyst use, minimizing energy consumption, and ensuring smooth processing even with varying oil feedstock. Its efficient purification cycle ensures clean biodiesel ready for generators, vehicles, agricultural machinery, and commercial selling.

HOW THE BIODIESEL PRODUCTION PROCESS WORKS

Before entering the main reaction cycle, the system prepares the feedstock oil for efficient conversion. This ensures smoother processing and consistent biodiesel quality across every batch.

Step 1: Oil Pre-Treatment

Used oil is filtered to remove moisture, impurities, and solid residues that affect reaction performance.

Step 2: Heating & Mixing

The oil is heated and blended with a controlled mix of methanol and catalyst to begin the transesterification process.

Step 3: Transesterification Reaction

Fatty acids react with the alcohol to form biodiesel and glycerin under regulated temperature and mixing.

Step 4: Separation

Biodiesel and glycerin naturally separate or are divided using settling or centrifugal systems.

Step 5: Washing & Purification

The biodiesel is washed and dried to remove remaining catalysts, balancing final fuel quality.

Step 6: Final Biodiesel Output

The finished biodiesel is ready for generators, transport vehicles, burners, and commercial resale.

EXPLORE OUR RANGE OF HIGH-PERFORMANCE BIODIESEL MACHINES

EXPLORE OUR RANGE OF HIGH-PERFORMANCE

BIODIESEL MACHINES

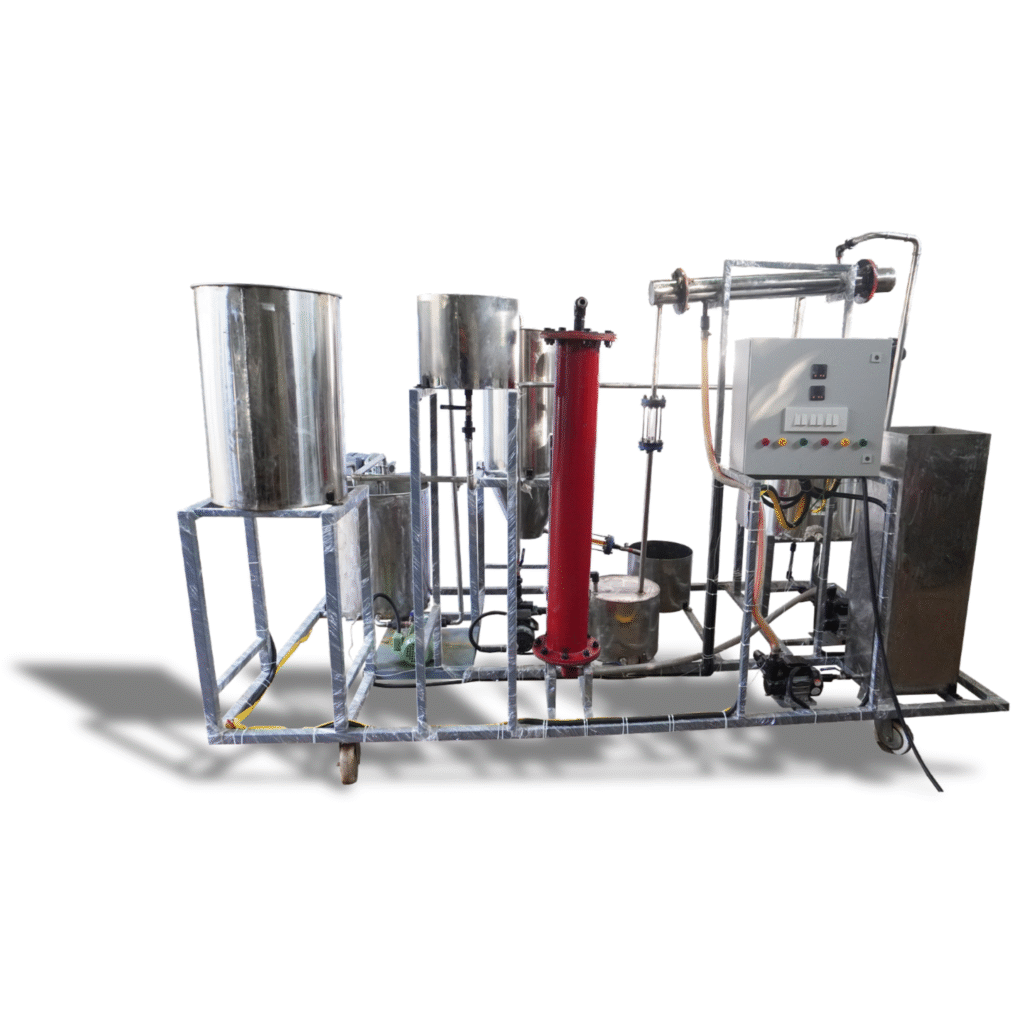

VEERA BD200SC – BIODIESEL CONVERSION SYSTEM

$2800-5500 / Unit

The VEERA BD200SC is a small-footprint biodiesel machine engineered for efficient fuel conversion from used cooking oil and vegetable oil. It features a controlled reaction chamber, precise temperature regulation, and simplified operation, making it suitable for entry-level biodiesel production, testing facilities, and decentralized fuel generation.

VEERA BD500SC – AUTOMATED BIODIESEL PROCESSING PLANT

$4800-7500 / Unit

Built for continuous biodiesel manufacturing, the VEERA BD500SC integrates automated mixing, catalyst dosing, and phase separation into a single streamlined system. It is designed to maintain stable fuel quality while reducing manual intervention, making it an excellent choice for commercial producers seeking consistent output and operational efficiency.

VEERA BD1000SC – LARGE-SCALE BIODIESEL MANUFACTURING UNIT

$5500-9500 / Unit

The VEERA BD1000SC is an industrial-grade biodiesel solution developed for high-capacity production environments. Equipped with advanced processing controls, integrated washing, and fuel purification mechanisms, it supports continuous operation while meeting stringent biodiesel quality standards and long-term production demands.

OPERATIONAL HIGHLIGHTS OF OUR BIODIESEL MACHINE

Built for continuous industrial production with stable reaction control

Optimized energy usage for reduced operational costs

Consistent conversion efficiency across different oil feedstocks

High-grade reactor materials for durability and long system life

User-friendly operating system with automated process support

Engineered to deliver fuel-grade biodiesel with clean combustion quality

WHY CHOOSE OUR BIODIESEL MACHINE

This system is engineered using Veera Group’s expertise in renewable fuel machinery and industrial processing technology. Every model is developed to offer dependable output, efficient energy usage, and consistent biodiesel quality. With durable components, structured reaction control, and long service capability, the machine performs reliably across demanding operations. It supports both small and large facilities, ensuring cost-effective production and long-term value.

READY TO BEGIN YOUR BIODIESEL PRODUCTION PROJECT?

Veera Group can help you select the right Biodiesel Machine model, discuss capacity needs, share pricing options, and support installation planning. Tell us your requirements—our team will guide you Beyond to the right solution.

FAQs

What raw materials can be used in the Biodiesel Machine?

The system processes used cooking oil, vegetable oils, animal fats, and industrial waste oils suitable for transesterification.

It handles a wide range of feedstocks with consistent output quality.

This flexibility makes it practical for both small and large producers.

What is the typical biodiesel yield rate?

Yield depends on feedstock purity, but most users achieve high conversion efficiency with stable output.

Proper pre-filtration and correct catalyst ratios help maximize yield.

The machine is designed to maintain predictable results batch after batch.

Does the Biodiesel Machine require frequent maintenance?

Routine inspection of valves, pumps, and filters ensures smooth operation.

The system’s industrial-grade components are built for long service life.

Most users experience minimal downtime with regular checks.

Can this machine operate continuously?

Yes, selected models support continuous processing with stable heating and mixing control.

Temperature and catalyst flows remain consistent throughout the cycle.

This allows producers to run extended production schedules.

Which industries commonly use the Biodiesel Machine?

Fuel production companies, recycling units, commercial farms, and transport sectors.

It is also used in power generation and heating fuel applications.

Any operation needing clean-burning renewable fuel benefits from this system.