Our Story | Veera Groups

Survival to Sustainability

From nothing to everything, the journey of a decadent global brand in sustainability began from a survival story in a small village of Vayallur, where the vision to transform waste oil to diesel was born. We wish to share with you our story… Come take a look.

Proud farmer and engineering graduate with a craze for creation, Mr. Venkatesh Prabu Jayaram turns down a 7-figure job at a German company to pursue entrepreneurship at age of 24

Entering into the field of renewables with installation, repair, maintenance, fault detection and operation of wind turbines through VBK Fibers.

A life changing visit to China opening up huge supply chain collaborations on alternative energy including Shenzhen Effsun Wind Power Co.Ltd for manufacturing of wind mills

Expanding into fabrication and design of small-scale biomass gasifiers under MRC Green Energy; with a goal of creating an energy park dedicated to renewables. Solving for nature couldn’t have begun at a better place than at very own heart of nature itself

Farm to Factory first ever model of our containerized 100% TAR FREE and novel AIR-PREHEATING technology biomass gasifier manufactured and shipped to Belgium

Presenting our first CANOPY Model gasifier in South Africa conference for gas supply using macadamia nut shells as feedstock having high calorific value and abundant in South Africa

Milestone international project with United States client on energy crop cultivation such as King Giant Grass and switch grass for fuel extraction from agricultural wastes

Disrupting the restaurant chain with launch of our unique product and business model for Biomass pellet stove and multi-fuel stove first ever SMOKELESS and ZERO HEAT design. Value proposition for replacing LPG with biomass pellet stove guaranteed cost savings of 50% added leasing model deferred capital investments promotion green energy

100+ happy clients in South India RS Enterprises, EK Infrastructure, Ellred Foundation, Akshaya Food industry, JS canteen other medium small food chains

Birth of Sakthi Veera Green Energy Pvt. Ltd and brand of VEERA BIOPOWER the ultimate destination for alternative energy. Including novel biomass gasifier technology, biomass pellets production for heat energy applications.

SVGE First factory being constructed at Palani, Tamil Nadu to keep up with demand of our novel small-scale biomass gasifiers across the globe

A point of learning and struggle for survival as a high school team parts ways, nevertheless the energy to excel was on all time high with Mr. Venkatesh and Ms. Uma Maheswari, a huge backbone

Another much requested launch via collaboration with UK entities for Biomass Pellet machines using various feedstock (sawdust, wood pellets etc.) for energy generation and cattle feed applications

Gaining momentum with several consulting projects in renewables, a need on municipal solid waste processing set our foot into dump yard waste processing machinery including small scale anerobic biogas digestors and plastic pyrolysis units. Initiation of our project of pride on alternative energy generation in rural areas along with NGO Hand in Hand

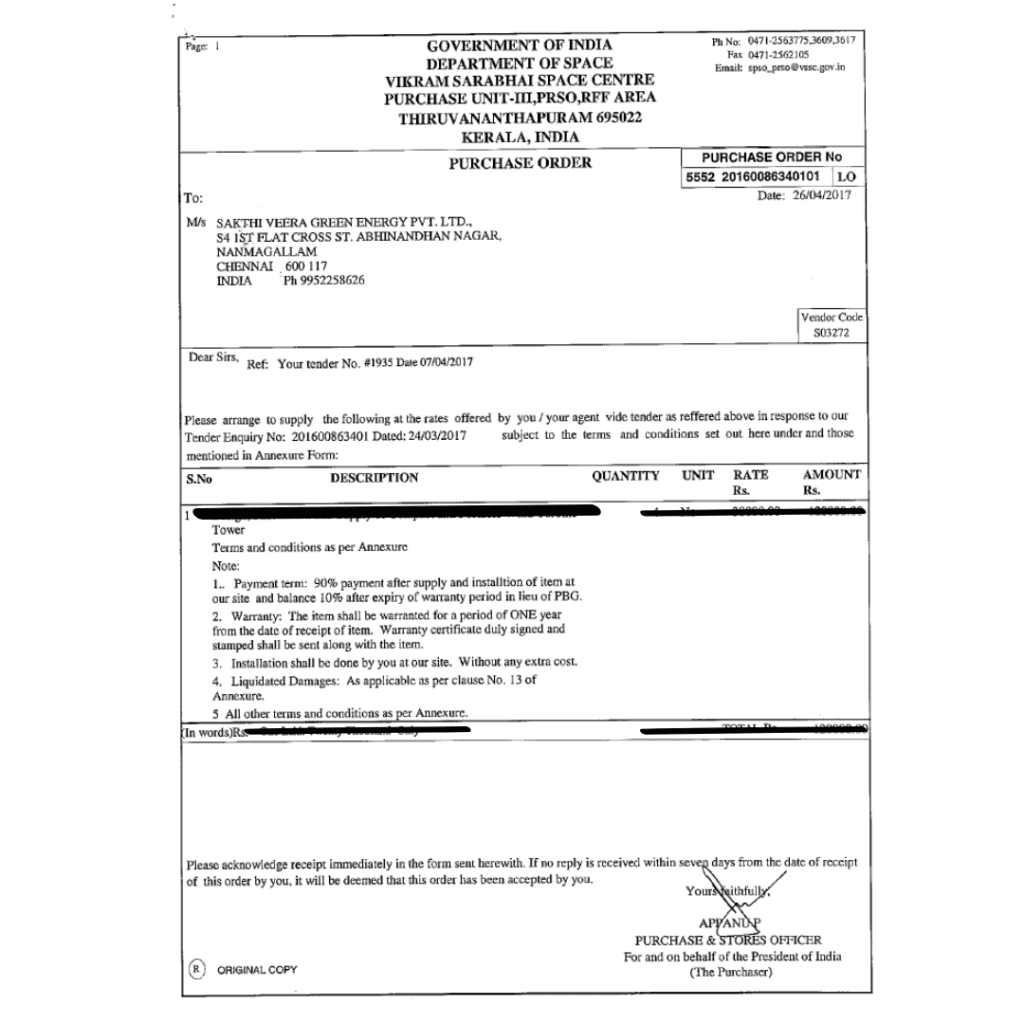

A huge feather in our cap being sanctioned a disaster management project for ISRO. Proud to supply solar and wind hybrid system for hydrogen fuel cell power generation

With the push from hearts that always have our growth in mind, Ms. Uma Maheswari secures the perfect warehouse for us in Chennai

A ground breaking launch of fully electric waste oil to diesel machine under VEERA BIOPOWER, India’s one and only novel and most affordable model for the global market

A niche consulting project paved way for the design of our smart energy saver cooking machines for restaurant chain with up to 60% time and labor savings with additional FREE HOT WATER by efficiently utilizing excess heat

Business on survival mode as COVID 19 hit, our lovely team stayed with us throughout the lows and technology transfers to major clients across Europe, Africa and South America kept us afloat

A grandiose in cooking technologies, the brand Attil Veera set in motion with research and development wing

Successfully shipping our value-added waste to energy machinery and technologies to nearly 40+ countries and celebrations with our new factory construction at Palani, Tamil Nadu.

A huge year indeed with one of our biggest orders from Mozambique client for three units of our hot selling VEERA D50C; getting an international recognition from World’s top e-commerce giant featuring us as a Success Story; forming our brand VEERA GROUP with our lovely family extended to Zambia and Kenya

With over 45+ countries in our clientele our standards have only increased with our international certifications of ISO 9001:2015; ISO 14001:2015 and CE accreditation

Excitement levels at peak as we receive the trademark for our VEERA GROUP

Our MISSION

To forefront decentralized small-scale sustainable machine technologies for energy generation from any and all forms of wastes.

Our VISION

To continually create technologies that create entrepreneurs with no compromise on simplicity, affordability, sustainability, and viability.

As we continue our journey in transforming waste oil to diesel, we’re committed to leading the way in sustainable energy solutions that not only reduce waste but also offer an eco-friendly alternative to traditional fuel sources. Converting waste oil to diesel is a highly innovative process that brings numerous benefits, from lowering carbon emissions to reducing dependency on fossil fuels. By embracing this advanced technology, we are paving the way for a cleaner and greener future.

The waste oil to diesel process not only helps in cutting down on industrial waste but also provides a cost-effective solution for businesses looking to reduce fuel expenses. This conversion creates a sustainable energy cycle, transforming what would have been discarded oil into high-quality diesel fuel. If you’re curious about the advantages of this cutting-edge approach, check out our blog on the top 5 benefits of waste oil to diesel conversion. By repurposing waste oil into usable diesel, we’re turning a potential environmental hazard into a valuable resource that can power vehicles, machinery, and more.

To explore the full range of our waste oil to diesel technologies and solutions, visit our services page. Here, we detail how our process is making a positive environmental impact and helping to create a cleaner, greener future.