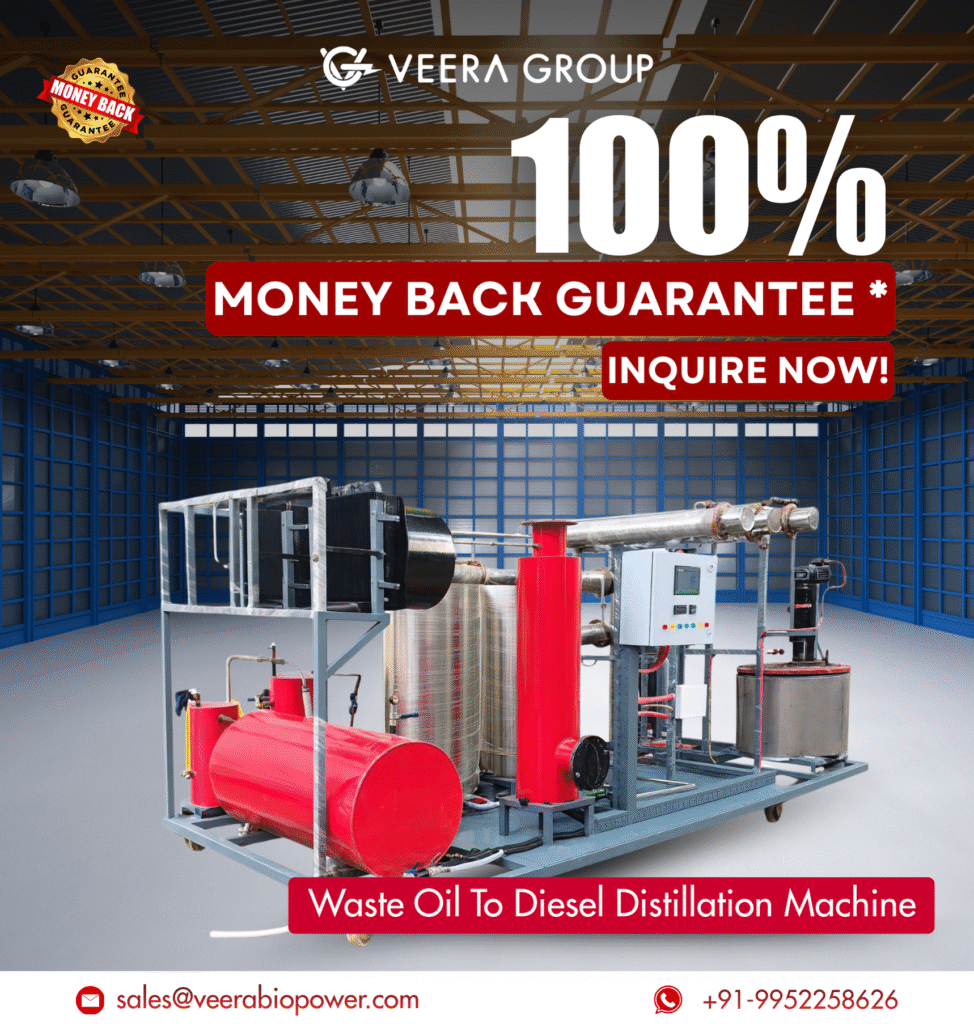

WASTE OIL TO DIESEL DISTILLATION MACHINE

The Waste Oil to Diesel Distillation Machine from Veera Group is built to convert used engine oil, hydraulic oil, and industrial lubricants into high-quality diesel through a controlled distillation and purification process. It supports recycling units, oil recovery plants, and fuel production facilities that require dependable output and long-term operational efficiency.

Key Advantages :

Converts multiple waste oils into clean, stable diesel

Designed for continuous industrial operation

Optimized heating and vacuum balance

Durable build with consistent fuel quality

Suitable for small and large production setups

The system transforms waste oil into usable fuel with reduced impurities and lower operating costs, offering a reliable solution for businesses seeking steady diesel recovery and sustainable processing performance.

HOW THE DISTILLATION PROCESS WORKS

The waste oil to diesel system follows a structured distillation workflow that ensures consistent fuel quality and high recovery efficiency.

Step 1: Oil Pre-Treatment

Waste oil is filtered to remove moisture, dust, sludge, and solid contaminants before entering the system.

Step 2: Controlled Heating & Evaporation

The pre-treated oil is heated inside the reactor. Under vacuum conditions, hydrocarbons evaporate at lower temperatures, preventing cracking and maintaining oil stability.

Step 3: Fractional Distillation

Vaporized hydrocarbons move through separation columns that isolate lighter fractions from heavier residues.

Step 4: Diesel Fraction Condensation

Diesel vapors are cooled through an efficient condensation unit and collected as clean liquid fuel.

Step 5: Purification & Polishing

A specialized purification process reduces sulfur, removes odor, and improves clarity to achieve stable, high-quality diesel.

Step 6: Final Diesel Output

The refined diesel is ready for industrial generators, burners, machinery, or commercial resale applications.

EXPLORE OUR RANGE OF HIGH-PERFORMANCE WASTE OIL TO DIESEL MACHINES

EXPLORE OUR RANGE OF HIGH-PERFORMANCE

WASTE OIL TO DIESEL MACHINES

VEERA MD50SC – ADVANCED MOLECULAR DISTILLATION

$4900 / Unit

Compact and efficient, the MD50SC produces high-quality diesel using low-temperature molecular separation. Ideal for units requiring stability, safety, and consistent batch performance.

VEERA MD100SC – CONTINUOUS DISTILLATION SYSTEM

$7500 / Unit

A robust waste oil to diesel conversion system delivering up to 85% yield efficiency. Engineered for continuous use with SS304 reactor construction and proprietary catalyst technology.

VEERA MD200SC – INDUSTRIAL DISTILLATION PLANT

$11500 / Unit

Designed for large-scale facilities, this model converts up to 300 litres per cycle using advanced cooling systems and remote monitoring. Its low-emission design supports clean diesel production.

OPERATIONAL EXCELLENCE AND ENGINEERING HIGHLIGHTS

Built for continuous, uninterrupted industrial performance

Optimized energy usage for cost-efficient operation

High conversion efficiency with minimal residue

Works with multiple categories of used oil

Precision-engineered with corrosion-resistant materials

User-friendly monitoring and control interface

Extended service life with reduced downtime

WHY CHOOSE OUR WASTE OIL TO DIESEL MACHINE

This system is developed with Veera Group’s experience in advanced distillation and recycling technology. Every model is engineered to deliver dependable output, long operational life, and reduced maintenance. High-grade materials, refined heating mechanisms, and controlled process design ensure stable performance in demanding environments. Whether you operate a small unit or a full-scale plant, this machine provides long-term value and flexibility for your production needs.

READY TO START YOUR WASTE OIL TO DIESEL PROJECT?

Veera Group can assist with machine selection, capacity planning, pricing information, and installation support. Share your requirements, and we’ll help you move Beyond with the right solution.

FAQs

What does the Waste Oil to Diesel Machine convert?

It converts used engine oil, hydraulic oil, lubricants, and similar waste oils into clean diesel.

The process removes moisture, sludge, and impurities through distillation and purification.

The final output is stable, filtered diesel suitable for multiple industrial applications.

What is the expected diesel yield?

Yield typically ranges between 80–85% depending on the quality of the input oil.

Consistent heating and vacuum control help maintain stable conversion rates.

Higher-grade waste oil generally results in improved recovery efficiency.

Can the machine run continuously?

Yes, most models support continuous or extended operation cycles.

The system stabilizes temperature and vacuum levels for uninterrupted processing.

This allows consistent diesel output without frequent shutdowns.

Does the machine require high maintenance?

The machine is built for stable, low-maintenance operation with reliable internal components.

Regular inspections of basic parts like pumps and heating elements are usually sufficient.

Most facilities run it continuously with very minimal servicing needs.

How many people are needed to operate the machine?

One trained operator is usually sufficient for day-to-day machine handling.

The automated controls simplify feeding, heating, and monitoring tasks.

Larger systems may require an assistant during loading or unloading cycles.